Further development and modernization of existing industrial systems and machines

Updating operating systems, which become risky in the absence of support, is inevitable, both from a safety and comfort point of view. We have extensive knowledge in the following areas:

- Virtualization on multiple platforms

- Update operating systems

- Patching unsupported software and hardware

- Replacement of serviced hardware elements

- Integration of new technologies

- Modernization of manual workstations.

How does a system modernization take place?

1. Renovation of the PLC system:

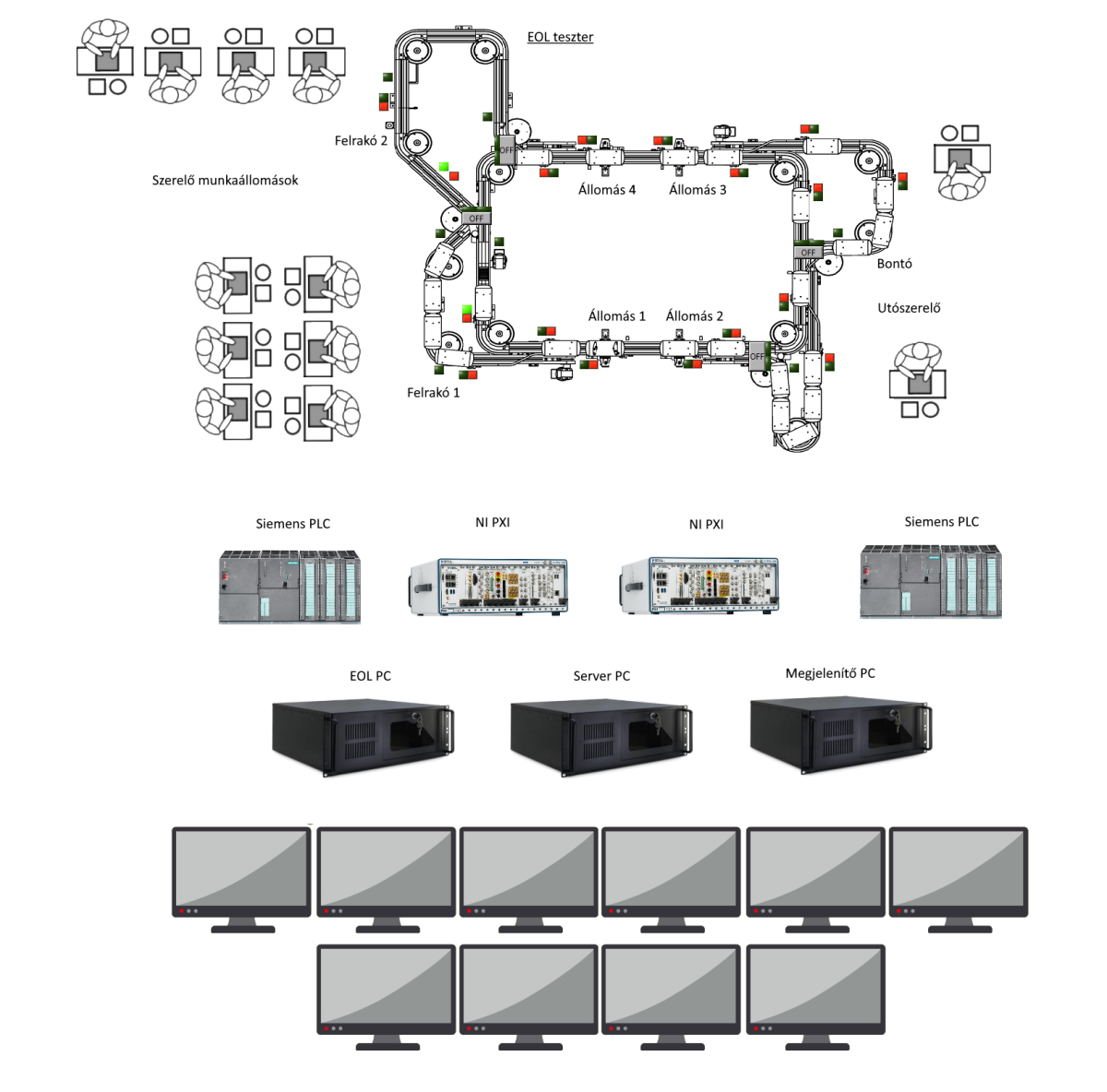

The production line was commissioned in 2011. The assembly workstations (10 units) are controlled by a Siemens PLC-based system, which, in addition to the Siemens HMIs, is accompanied by a central software written in the LABVIEW language.

The automatic EOL testers are controlled by an NI PXI-based system, for which the software was written in the LABVIEW language. The line's original manufacturer support has ended, and a complete rewrite of the EOL testers' software became necessary in 2014. Real-time control and measurement is performed by 2 National Instruments PXI, the series communicates with the peripherals via the DeviceNet network. The products arriving at the EOL testers are tested based on RfID information and forwarded to the reassembly station.

On the other hand, the reliability of the retrofitting was not sufficient, so in 2021 the software controlling the retrofitting and the related Siemens PLC programs also had to be significantly rewritten. The originally used protocol based on OPC and several smaller unique protocols was replaced by a unified form of communication, and all the contact mechanisms (handshake) were redesigned.

2. CVI program transformation:

The supply of spare parts for the hardware of the EOL tester has ceased, its operating system is out of date, so the modernization of the system has become necessary.

The old hardware is an ISA / PCI bus P4 motherboard with an ISA bus digital IO card. The software environment was CVI 5.0 running on Windows XP.

The new configuration is based on Windows 10 and runs with the LabWindows CVI 2009 SP1 development environment. In addition to the Multi IO card and the CAN bus card, two PCIe Digital IO cards were added.

The full description is available here: Link

3. Linux-based virtualization

One of the specializations of Omega Byte Kft. is that the computers they supervise, on which production-critical applications and related measurements run, are always have to be operational. Thanks to the support of Windows XP officially ending on April 14, 2014 - and the end of an era - the latter can be expected for several machines in the future, which unfortunately makes it difficult to operate the devices in question. In many cases, the expansion cards installed in PCs do not support operating systems newer than Windows XP, since they were purchased sometime during the Win95 - Win98 period (more than 20 years ago).

Another problem is that in order to replace the cards mentioned above, the complete production line would have to be reprogrammed, which is very expensive and time-consuming - adding that all this would have to be done because of a single downed computer.

Our preferred solution to the situation is Windows XP running in a virtual environment, which can also be functional in the long term. With one or two exceptions, all kinds of devices can be virtualized and, moreover, the physical layer underneath can be replaced at any time by observing one or two conditions.

The full description is available here: Link